INTRODUCTION

Tapered roller bearings are among the most essential components in mechanical systems involving rotational motion, especially where axial and radial loads must be accommodated. They are widely used in automotive, heavy machinery, and industrial applications. To ensure their performance, safety, and reliability, standardized manufacturing and quality control practices are crucial. This is where the Bureau of Indian Standards (BIS) certification, as per IS 12102, comes into play.

This article provides a comprehensive look at Indian Standard IS 12102:1987, which governs the specifications for single-row tapered roller bearings. It also discusses the BIS certification process for manufacturers and how Omega QMS Pvt. Ltd. assists manufacturers in achieving and maintaining this certification.

UNDERSTANDING INDIAN STANDARD IS 12102:1987

IS 12102:1987 is the Indian Standard that specifies the technical and dimensional requirements for single-row metric tapered roller bearings. The standard ensures uniformity in manufacturing and performance across different manufacturers and applications.

Key Elements of IS 12102

Material Requirements:

Materials must comply with IS 6453:1984, which outlines the technical supply conditions for rolling bearings.

Dimensional Requirements:

Boundary Dimensions: As per IS 7461:1980.

Tolerances: Governed by IS 7460:1974.

Chamfer Dimensions: Defined in IS 5934:1987.

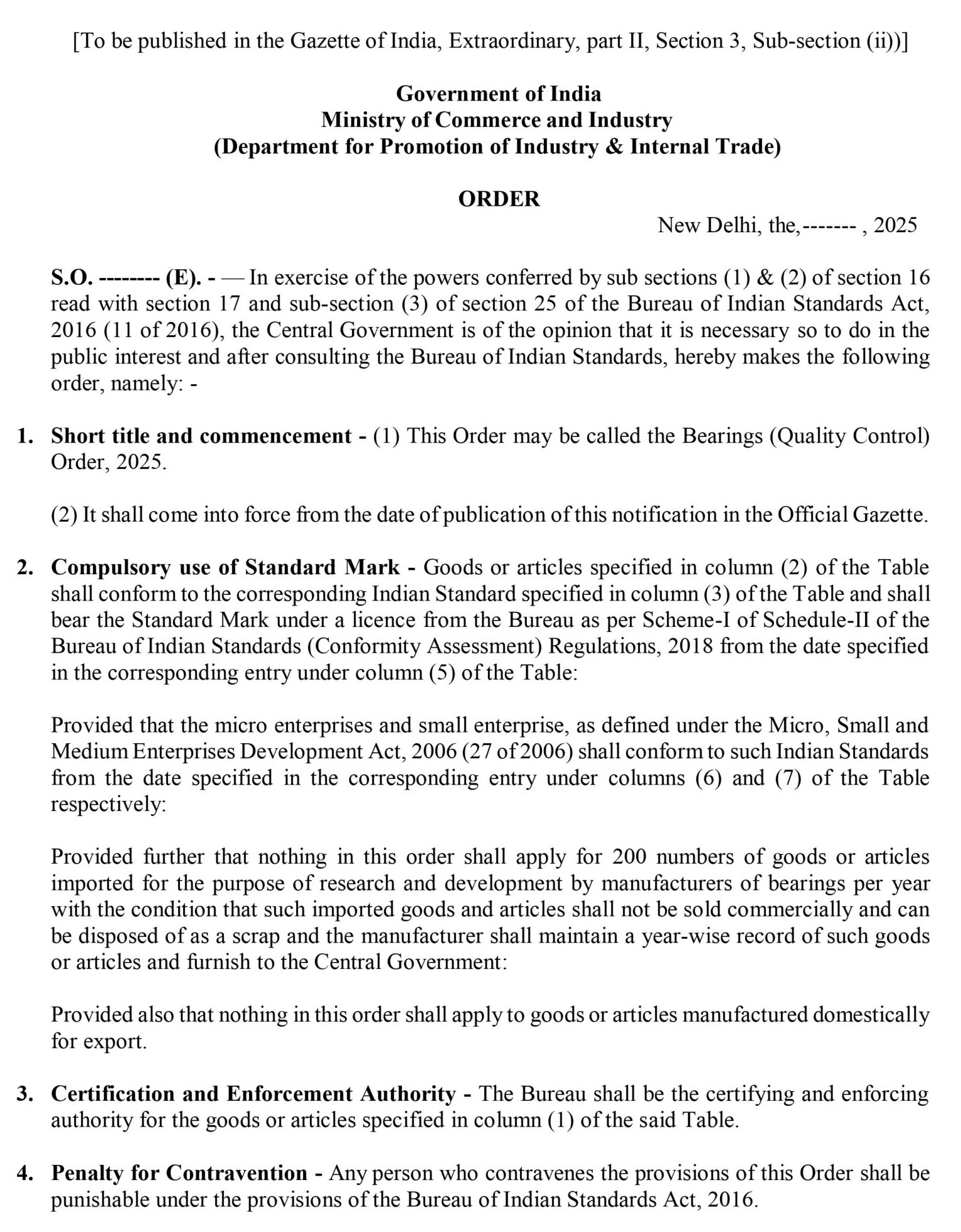

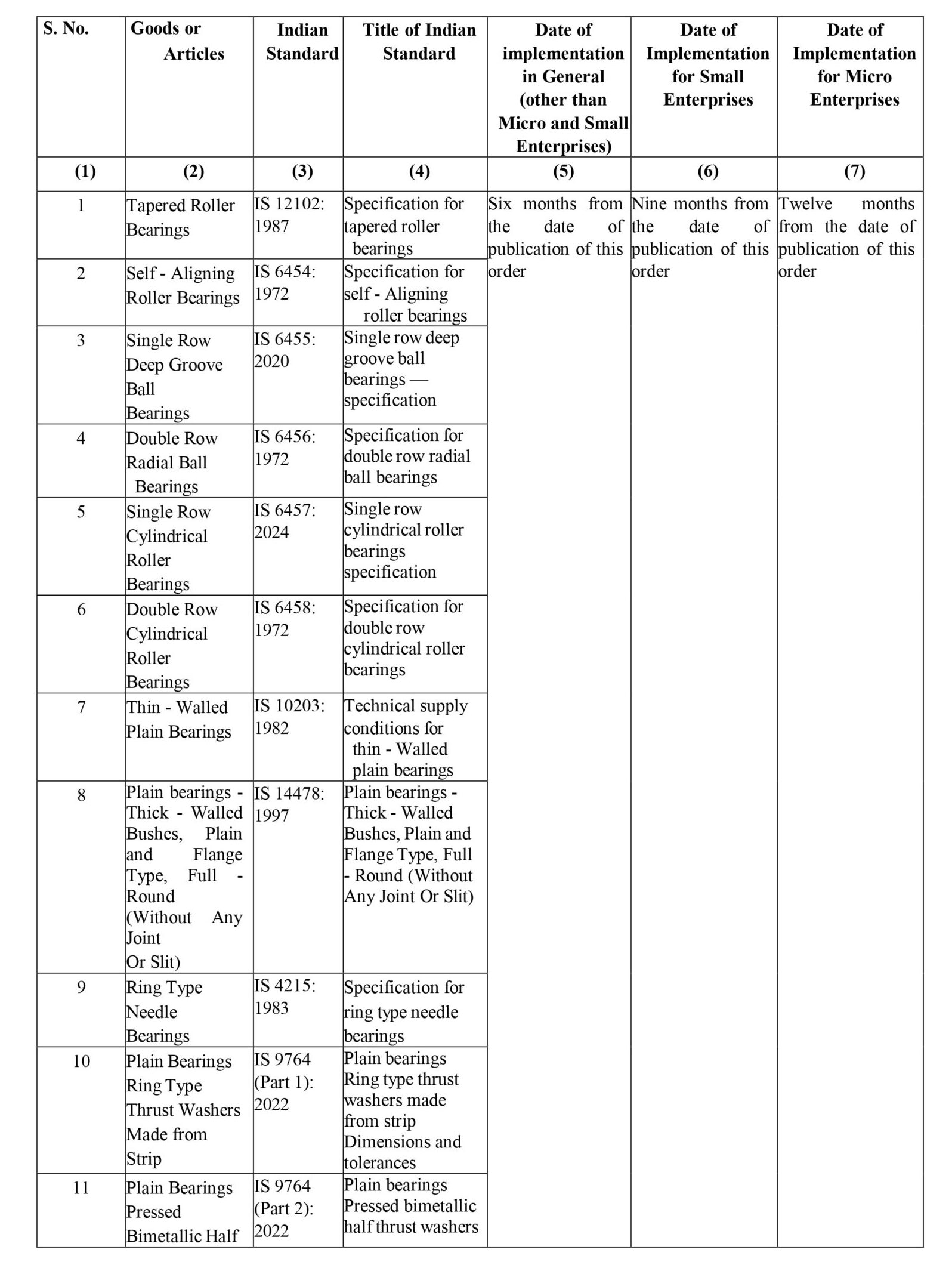

OVERVIEW OF THE QCO FOR BEARINGS

Quality Control Orders, or QCOs are a regulatory mechanism introduced by Ministry of Commerce under Bureau of Indian Standards (BIS) Act. They aim to ensure that products meet a minimum standard of quality and safety before being sold in the Indian market. For international traders, this means complying with BIS certification before exporting products like bearings to India.

India’s draft QCO for bearings emphasizes the quality standards and certification requirements for manufacturers, importers, and suppliers of these metals. The document mandates that all primary metals must conform to the relevant Indian Standards and manufacturers must obtain BIS certification before selling or distributing lead products in India.

BIS CERTIFICATION PROCESS FOR TAPERED ROLLER BEARINGS UNDER IS 12102

The BIS certification process for tapered roller bearings ensures that the products conform to IS 12102 and meet stringent quality parameters. The certification follows a well-defined conformity assessment scheme under the BIS Act, 2016.

Steps Involved:

Application Submission: The manufacturer applies to BIS with product and factory details.

Product Testing: Samples are drawn from the production lot and tested for compliance with IS 12102 in BIS-recognized laboratories.

Factory Audit: BIS officers inspect the manufacturing process, quality control mechanisms, raw material traceability, and testing infrastructure.

Grant of License: If the product meets all specifications and the factory adheres to BIS standards, a license is granted to use the Standard Mark.

Ongoing Surveillance: BIS conducts periodic surveillance inspections and draws samples from the market or factory for re-testing.

HOW OMEGA QMS PVT. LTD. SUPPORTS MANUFACTURERS

Omega QMS Pvt. Ltd. is a leading consultancy specializing in helping manufacturers obtain and maintain BIS certification. For tapered roller bearings under IS 12102, Omega QMS plays a vital role in simplifying the certification journey.

Services Provided:

Initial Gap Analysis: Assessing the manufacturer’s current compliance against IS 12102 and identifying areas for improvement.

Documentation Support: Preparation of technical documentation, and application papers required by BIS.

Factory Readiness Audits: Conducting mock audits to ensure the facility is ready for BIS inspection.

Liaison with BIS Authorities: Handling communication, application submission, and coordination for inspections and testing.

Post-Certification Support: Assistance in maintaining compliance during surveillance audits and for renewal of certification.

With Omega QMS by their side, manufacturers can focus on production while leaving the complex compliance process to the experts.

CONCLUSION

IS 12102:1987 provides a robust and standardized framework for the design, manufacture, and quality assurance of single-row tapered roller bearings. Compliance with this standard through BIS certification ensures product safety, reliability, and acceptance in both domestic and international markets.

Manufacturers aiming to achieve this certification benefit greatly from the expert guidance of organizations like Omega QMS Pvt. Ltd., whose comprehensive support ensures a smooth and successful certification process.

FINAL THOUGHTS

In a competitive industrial landscape, standard compliance is no longer optional—it is essential. The Indian Standard IS 12102 and BIS certification offer a clear path for manufacturers to demonstrate quality and reliability in their products. With a trusted partner like Omega QMS Pvt. Ltd., navigating the certification journey becomes efficient, accurate, and stress-free.

OMEGA QMS PVT. LTD.

908-909, Hemkunt House, Rajendra Place, New Delhi-110008, India

Phone: 011-41413939(100 lines), Email: info@globalomega.com,

sales@globalomega.com, mktg@globalomega.com