In today’s highly regulated manufacturing environment, product quality and safety compliance are no longer optional—they are strategic imperatives. One key example of this is the mandatory BIS certification for Acrylonitrile Butadiene Styrene (ABS) under India’s Quality Control Orders (QCO). For manufacturers and importers of ABS, navigating the Bureau of Indian Standards (BIS) certification process can be complex and time-consuming. This is where Omega QMS Pvt. Ltd. steps in as a trusted partner in compliance.

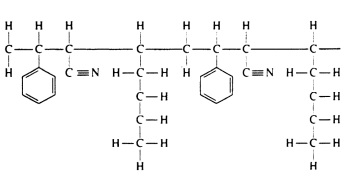

What is ABS and Why is it Regulated?

Acrylonitrile Butadiene Styrene (ABS) is a widely used thermoplastic polymer known for its strength, toughness, and impact resistance. It finds extensive applications in the automotive, electrical, consumer goods, and construction industries.

Given its critical use in end-consumer applications, the Ministry of Chemicals and Fertilizers issued the ABS (Quality Control) Order, 2021, mandating that ABS products conform to specific Indian standards to ensure consistent quality and safety.

The Legal Mandate: Quality Control Order (QCO) for ABS

Effective from March 2022, ABS materials are now subject to compulsory certification under the Bureau of Indian Standards Act, 2016. As per the QCO:

- ABS materials must conform to IS 17077:2019(or ISO 19062-1:2015).

- The use of the Standard Mark (ISI mark)is mandatory.

- Certification must be obtained through Scheme-I of Schedule-IIof the BIS (Conformity Assessment) Regulations, 2018.

- Non-compliance can attract penalties under the BIS Act.

This move ensures consumer safety, product reliability, and promotes the use of standardized raw materials across industries.

What Does IS 17077:2022 Cover?

- The updated IS 17077 (Part 1): 2022provides a comprehensive framework for:

- Material classification and designation system.

- Testing requirements such as Vicat softening temperature, melt flow rate, impact strength, and tensile modulus.

- Marking, packaging, and labeling.

- Special provisions for materials in contact with food, pharmaceuticals, or drinking water.

This standard ensures that ABS materials are not only functionally robust but also environmentally and health-safe.

Omega QMS Pvt. Ltd.: Your Partner for Seamless BIS Certification

Securing a BIS license can be a rigorous and technical process involving sample testing, documentation, audits, and regulatory interpretation. Omega QMS Pvt. Ltd., a recognized compliance and certification advisory firm, simplifies this journey for the industry.

How Omega QMS Adds Value:

- End-to-End BIS Consulting: From application to audit, we manage it all.

- Documentation Support: Preparation of technical files, drawings, and compliance records.

- Testing Coordination: Assistance in submitting samples to BIS-recognized labs.

- Inspection & Audit Readiness: Factory setup and process alignment as per BIS norms.

- Expertise in Foreign Certifications: Support for international manufacturers via Authorized Indian Representatives (AIRs).

- Timely Updates: Continuous monitoring of amendments and regulatory changes.

With Omega QMS, clients experience a faster, more reliable route to BIS certification, reducing risk and improving market access.

Conclusion

The mandatory BIS certification for ABS under IS 17077 reflects India’s strong push towards quality and standardization in industrial materials. For businesses in the polymer and plastic industry, this marks both a challenge and an opportunity. With the right guidance, such as from Omega QMS Pvt. Ltd., compliance becomes not just achievable but seamless.

If your organization manufactures, imports, or distributes ABS, now is the time to act. Let Omega QMS be your trusted compliance navigator.

Need help with BIS certification for ABS?

Contact Omega QMS Pvt. Ltd. today to get started on a seamless certification process.

![]()

Hemkunt House, Rajendra Place, New Delhi-110008,

India, Phone: 011-41413939(100 lines), Email: info@globalomega.com,

sales@globalomega.com, mktg@globalomega.com