INTRODUCTION

Needle bearings represent a specialized class of roller bearings characterized by their use of small cylindrical rollers that resemble needles. These precision components perform critical functions in various mechanical systems, particularly where space constraints exist alongside requirements for high load capacity. The distinctive design of needle bearings allows them to accommodate heavy radial loads while maintaining a relatively compact profile compared to other bearing types. Their applications span numerous industries including automotive transmissions, industrial machinery, aerospace systems, and heavy equipment where reliability under demanding conditions is essential.

The standardization of needle bearings through documents like IS 4215 plays a vital role in India’s manufacturing ecosystem. Standards establish a common technical language between manufacturers and customers, ensuring interchangeability, consistent performance, and reliable operation across applications. For components as critical as bearings, where failure can lead to catastrophic system breakdowns, adherence to standardized specifications becomes particularly important. The standardization process involves extensive testing, validation, and consensus-building among industry stakeholders to establish parameters that balance performance requirements with manufacturing feasibility.

In the mechanical engineering domain, BIS standards like IS 4215 align closely with international best practices while addressing specific requirements of the Indian market. The implementation of these standards is often facilitated by specialized quality management consultancies such as Omega QMS Pvt. Ltd., which provide expertise in quality systems, certification processes, and compliance strategies.

COMPREHENSIVE ANALYSIS OF IS 4215 SPECIFICATION

Scope and Classification

IS 4215 specifically addresses the requirements for needle bearings with thick rings designed for high-load and high-speed applications. The standard categorizes needle bearings into three primary types, each serving specific functional requirements in mechanical systems1. The first category encompasses radial needle bearings, which may feature either cage-guided needles or full complement retained needles. The second category covers needle thrust bearings, which handle axial loads. The third category includes combined needle bearings that can simultaneously manage both radial and thrust loads, making them suitable for complex applications with multi-directional forces1.

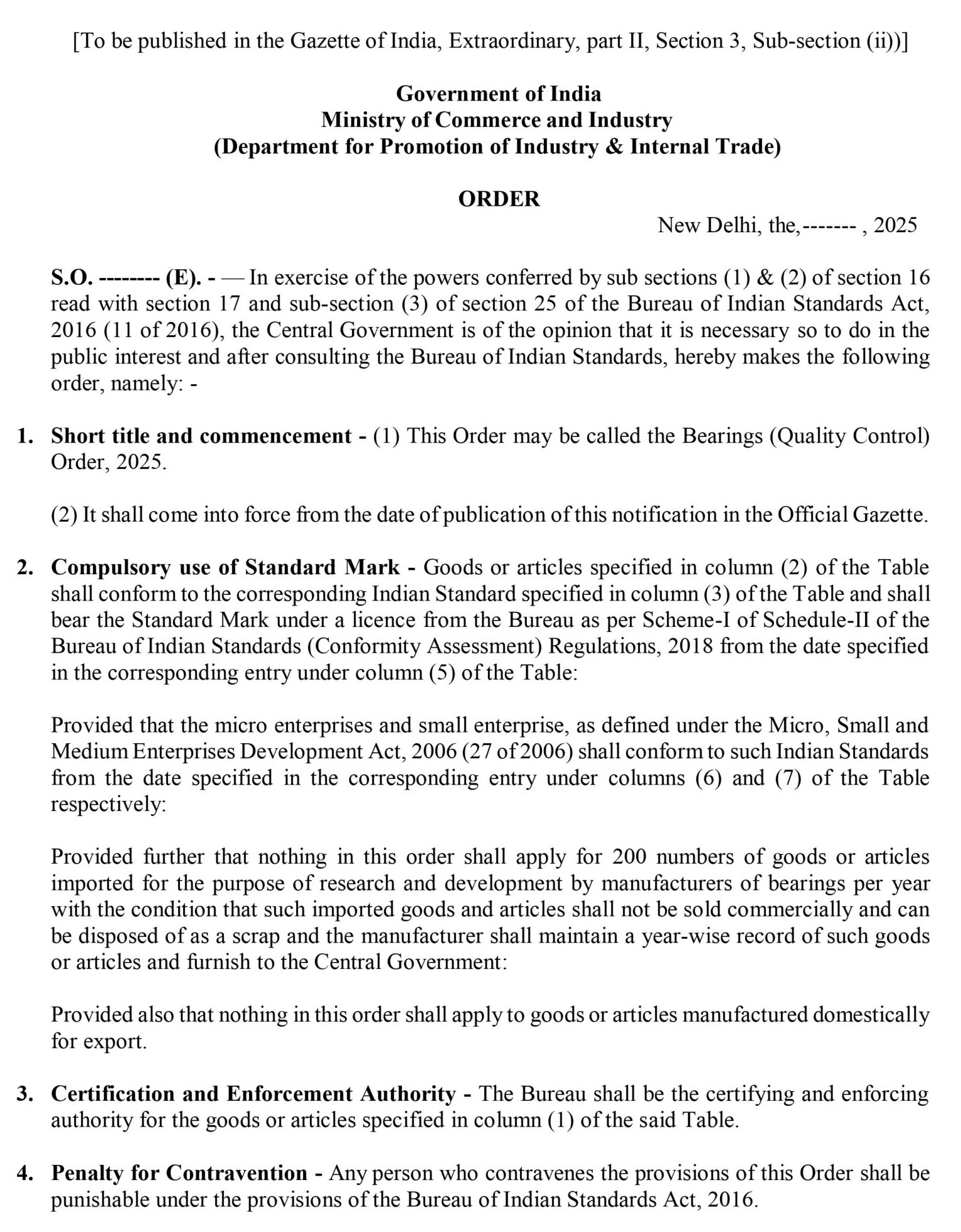

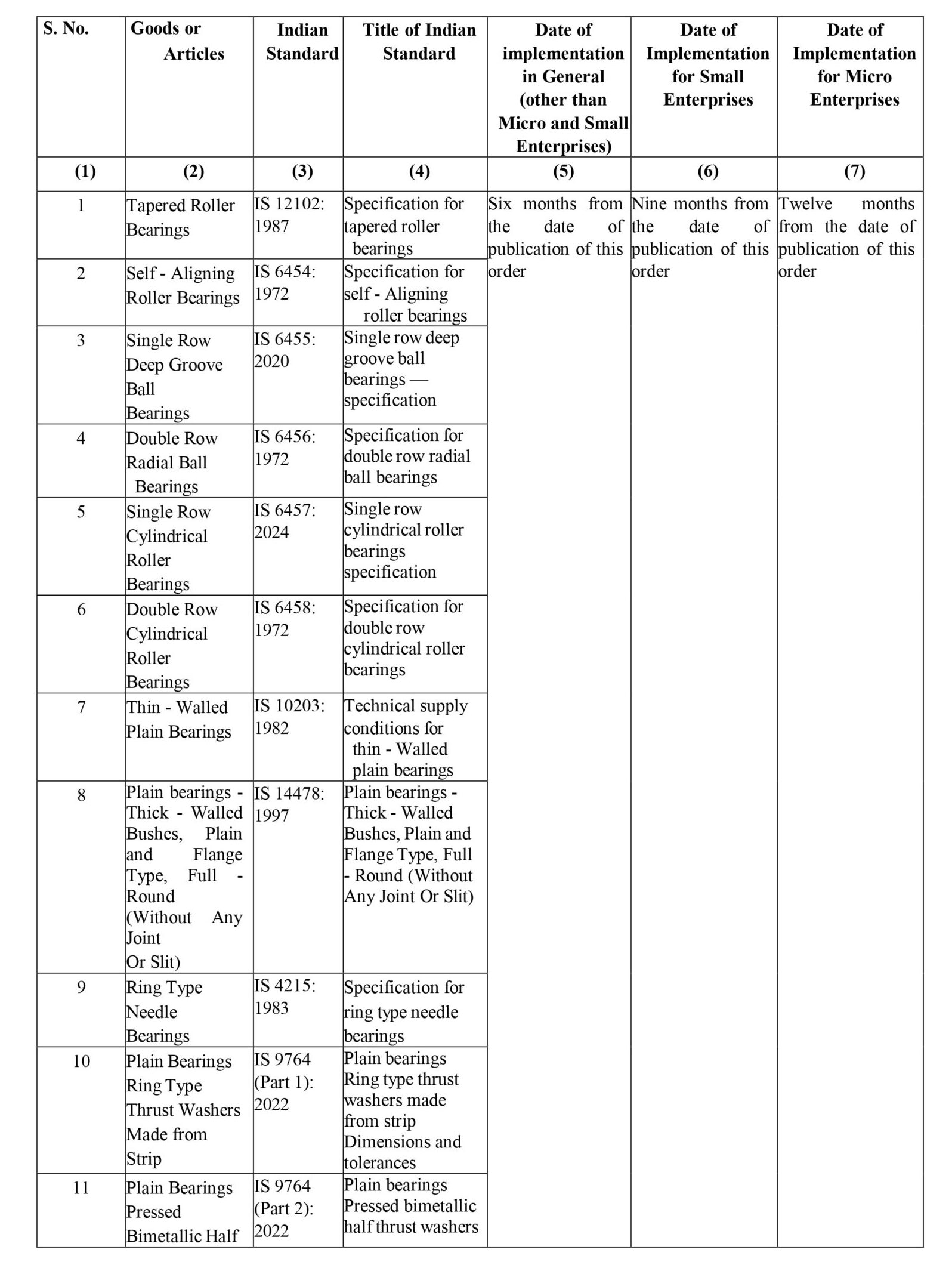

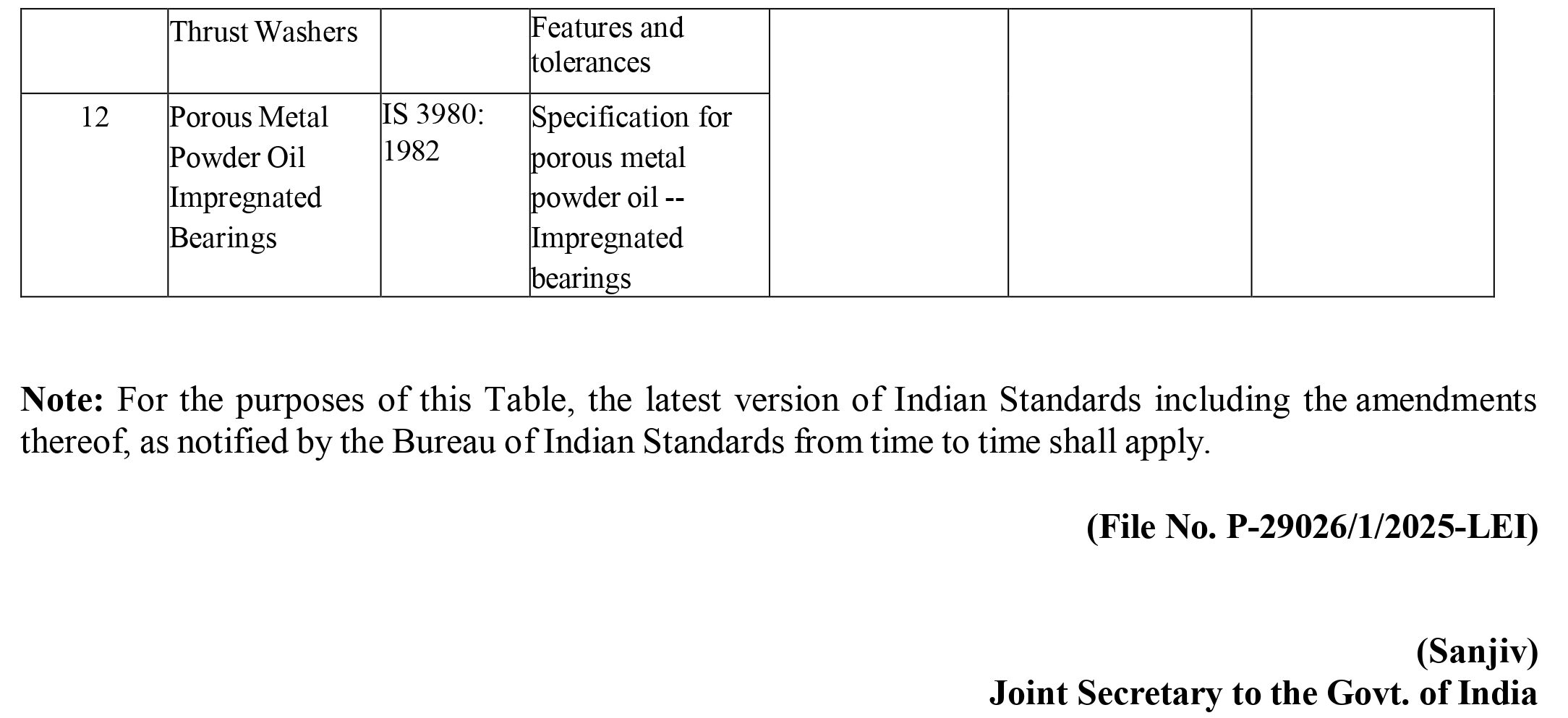

OVERVIEW OF THE QCO FOR BEARINGS

Quality Control Orders, or QCOs are a regulatory mechanism introduced by Ministry of Commerce under Bureau of Indian Standards (BIS) Act. They aim to ensure that products meet a minimum standard of quality and safety before being sold in the Indian market. For international traders, this means complying with BIS certification before exporting products like bearings to India.

India’s draft QCO for bearings emphasizes the quality standards and certification requirements for manufacturers, importers, and suppliers of these metals. The document mandates that all primary metals must conform to the relevant Indian Standards and manufacturers must obtain BIS certification before selling or distributing lead products in India.

BIS CERTIFICATION PROCESS FOR RING TYPE NEEDLE BEARINGS UNDER IS 4215

The BIS certification process for ring type needle bearings ensures that the products conform to IS 4215 and meet stringent quality parameters. The certification follows a well-defined conformity assessment scheme under the BIS Act, 2016.

Steps Involved:

Application Submission: The manufacturer applies to BIS with product and factory details.

Product Testing: Samples are drawn from the production lot and tested for compliance with IS 4215 in BIS-recognized laboratories.

Factory Audit: BIS officers inspect the manufacturing process, quality control mechanisms, raw material traceability, and testing infrastructure.

Grant of License: If the product meets all specifications and the factory adheres to BIS standards, a license is granted to use the Standard Mark.

Ongoing Surveillance: BIS conducts periodic surveillance inspections and draws samples from the market or factory for re-testing.

HOW OMEGA QMS PVT. LTD. SUPPORTS MANUFACTURERS

Omega QMS Pvt. Ltd. is a leading consultancy specializing in helping manufacturers obtain and maintain BIS certification. For ring type needle bearings under IS 4215, Omega QMS plays a vital role in simplifying the certification journey.

Services Provided:

Initial Gap Analysis: Assessing the manufacturer’s current compliance against IS 4215 and identifying areas for improvement.

Documentation Support: Preparation of technical documentation, and application papers required by BIS.

Factory Readiness Audits: Conducting mock audits to ensure the facility is ready for BIS inspection.

Liaison with BIS Authorities: Handling communication, application submission, and coordination for inspections and testing.

Post-Certification Support: Assistance in maintaining compliance during surveillance audits and for renewal of certification.

With Omega QMS by their side, manufacturers can focus on production while leaving the complex compliance process to the experts.

CONCLUSION

Looking toward the future, the needle bearing industry continues to evolve with advancements in materials science, manufacturing technologies, and application requirements. While IS 4215 provides a solid foundation for current needs, ongoing review and potential updates will be necessary to address emerging technologies and changing market demands. Potential areas for future standards development might include specifications for bearings using advanced materials, miniaturized designs for emerging applications, or enhanced performance parameters for extreme operating conditions.

The global harmonization of bearing standards represents another important direction, as manufacturing supply chains become increasingly international. Alignment between Indian standards like IS 4215 and international counterparts facilitates global trade, reduces redundant testing, and simplifies compliance for multinational manufacturers. Organizations like BIS and consulting firms such as Omega QMS Pvt. Ltd. will continue to play vital roles in this harmonization process, ensuring that Indian standards remain relevant, current, and aligned with global best practices while addressing specific national requirements.

OMEGA QMS PVT. LTD.

908-909, Hemkunt House, Rajendra Place, New Delhi-110008, India

Phone: 011-41413939(100 lines), Email: info@globalomega.com,

sales@globalomega.com, mktg@globalomega.com