INTRODUCTION: THE PRECISION BEHIND INDUSTRIAL PERFORMANCE

In the high-performance world of rotating machinery, single row cylindrical roller bearings are pivotal. They offer excellent radial load capacity, high-speed capability, and minimal friction—making them essential in industries like steel, automotive, power generation, and heavy equipment manufacturing.

To maintain performance integrity and safety, these bearings must adhere to stringent technical requirements. That’s where IS 6457, the Indian Standard for single row cylindrical roller bearings, steps in. The Bureau of Indian Standards (BIS) mandates conformity to IS 6457 for certification and market legitimacy. For manufacturers aiming to meet this standard efficiently, Omega QMS Pvt. Ltd. provides critical consultancy services to simplify the certification process.

SUMMARY OF INDIAN STANDARD IS 6457

Scope

Covers single row cylindrical roller bearings, including through-hardened and case-hardened types. Excludes airframe and instrument precision bearings.

Performance Criteria

Hardness: Minimum of 58 HRC for rings and rollers.

Surface Finish: Max permissible roughness (Ra) as per IS 3073—critical for minimizing wear and friction.

Radial Internal Clearance: Must conform to IS 5935 for optimal bearing fit and reduced noise.

Load Ratings:

Dynamic: As per IS 3824

Static: As per IS 3823

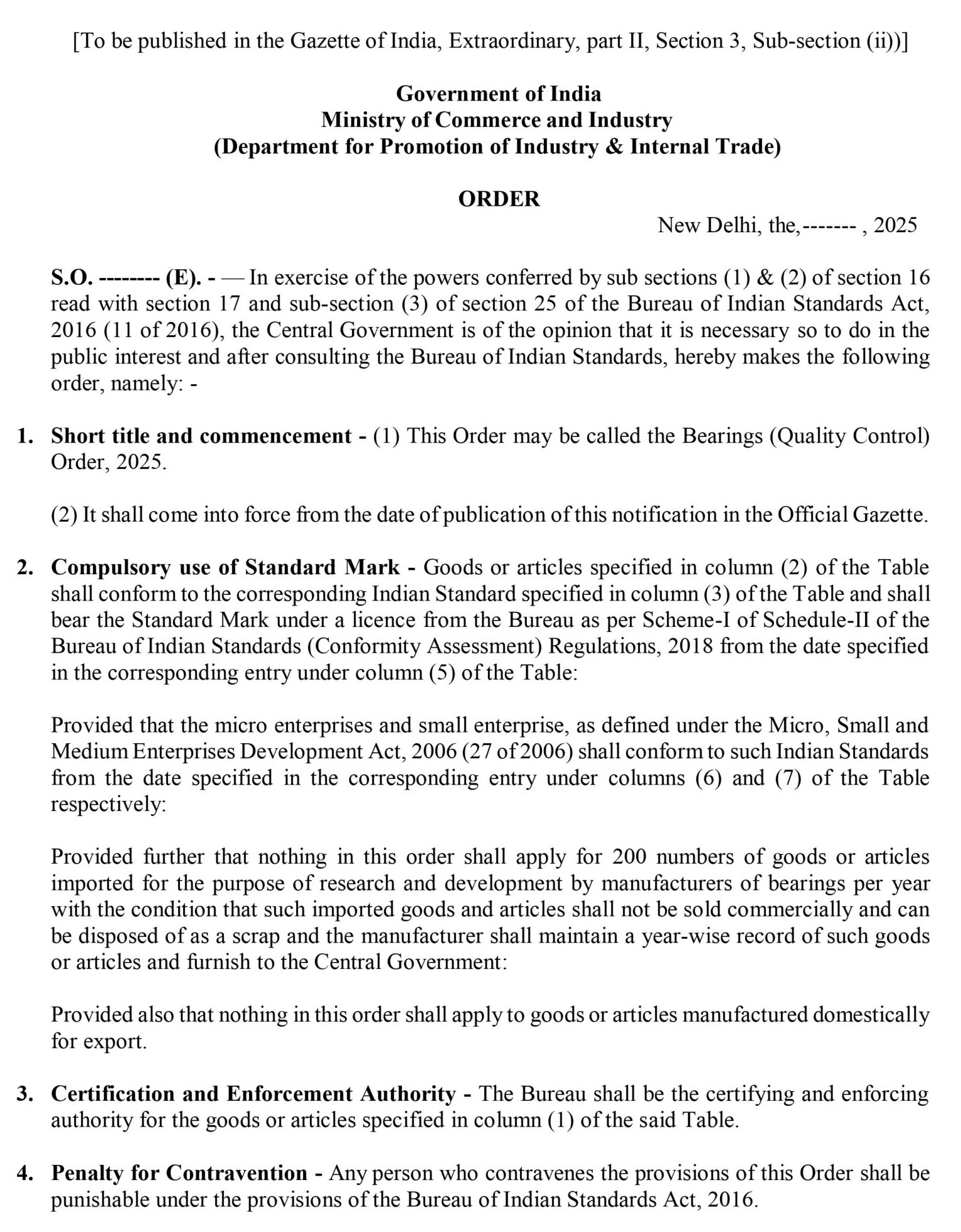

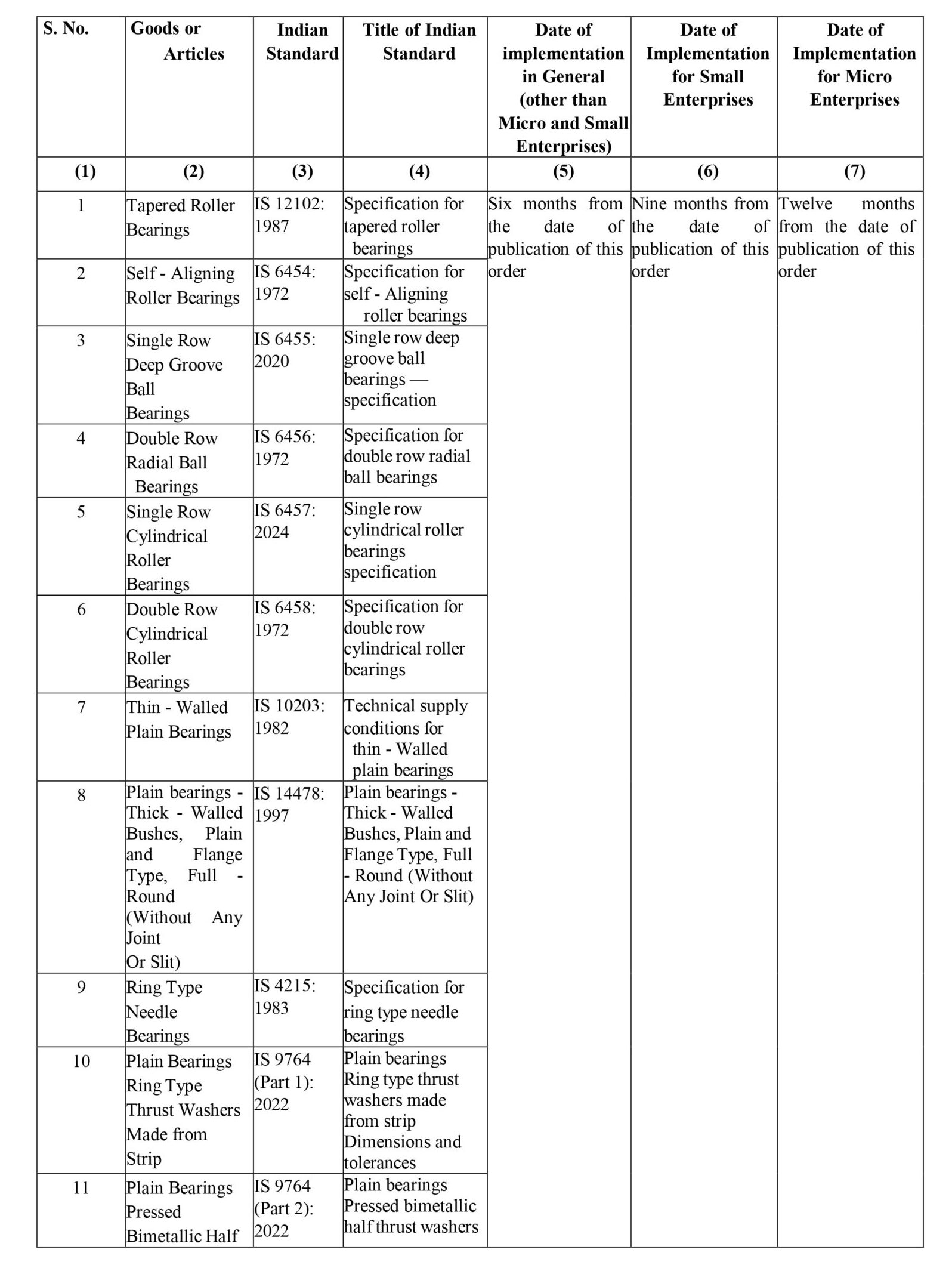

OVERVIEW OF THE QCO FOR BEARINGS

Quality Control Orders, or QCOs are a regulatory mechanism introduced by Ministry of Commerce under Bureau of Indian Standards (BIS) Act. They aim to ensure that products meet a minimum standard of quality and safety before being sold in the Indian market. For international traders, this means complying with BIS certification before exporting products like bearings to India.

India’s draft QCO for bearings emphasizes the quality standards and certification requirements for manufacturers, importers, and suppliers of these metals. The document mandates that all primary metals must conform to the relevant Indian Standards and manufacturers must obtain BIS certification before selling or distributing lead products in India.

BIS CERTIFICATION PROCESS FOR SINGLE ROW RADIAL ROLLER BEARINGS UNDER IS 6457

The BIS certification process for tapered roller bearings ensures that the products conform to IS 6457 and meet stringent quality parameters. The certification follows a well-defined conformity assessment scheme under the BIS Act, 2016.

Steps Involved:

Application Submission: The manufacturer applies to BIS with product and factory details.

Product Testing: Samples are drawn from the production lot and tested for compliance with IS 6457 in BIS-recognized laboratories.

Factory Audit: BIS officers inspect the manufacturing process, quality control mechanisms, raw material traceability, and testing infrastructure.

Grant of License: If the product meets all specifications and the factory adheres to BIS standards, a license is granted to use the Standard Mark.

Ongoing Surveillance: BIS conducts periodic surveillance inspections and draws samples from the market or factory for re-testing.

HOW OMEGA QMS PVT. LTD. SUPPORTS MANUFACTURERS

HOW OMEGA QMS PVT. LTD. SUPPORTS MANUFACTURERS

Omega QMS Pvt. Ltd. is a leading consultancy specializing in helping manufacturers obtain and maintain BIS certification. For single row radial ball bearings under IS 6457, Omega QMS plays a vital role in simplifying the certification journey.

Services Provided:

Initial Gap Analysis: Assessing the manufacturer’s current compliance against IS 6457 and identifying areas for improvement.

Documentation Support: Preparation of technical documentation, and application papers required by BIS.

Factory Readiness Audits: Conducting mock audits to ensure the facility is ready for BIS inspection.

Liaison with BIS Authorities: Handling communication, application submission, and coordination for inspections and testing.

Post-Certification Support: Assistance in maintaining compliance during surveillance audits and for renewal of certification.

With Omega QMS by their side, manufacturers can focus on production while leaving the complex compliance process to the experts.

CONCLUSION

IS 6457 brings Indian manufacturing in line with international expectations for single row cylindrical roller bearings. It establishes a thorough framework covering dimensions, material quality, performance tolerances, and packaging—ensuring that the final product meets demanding industrial applications.

For manufacturers, achieving BIS certification under IS 6457 is a clear statement of quality and reliability.

FINAL THOUGHT

Precision starts with the parts that make machines move. With IS 6457 and BIS certification, your bearings don’t just roll — they earn trust, enhance safety, and open markets. And when Omega QMS Pvt. Ltd. is guiding your certification journey, success is never out of reach.

OMEGA QMS PVT. LTD.

908-909, Hemkunt House, Rajendra Place, New Delhi-110008, India

Phone: 011-41413939(100 lines), Email: info@globalomega.com,

sales@globalomega.com, mktg@globalomega.com